Email us

BEL VALVES enjoys significant savings since installing a DANOBAT band saw

January 27, 2014

As industry leaders in the design and manufacture of critical oil and gas valves for both surface and subsea applications, Newcastle based BEL VALVES concentrate their energies on serving evolving markets that demand the very highest quality and reliability.

The company have in the region of 50,000 valves installed across the globe, some of which operate in the most inhospitable environments on the planet, often in ultra-deep waters of up to 10,000 feet and under high pressures as well as extremes of temperature.

With valve sizes ranging up to 48' in diameter and tolerances typically less than one micron, ultra precision machining is of the utmost importance, so when BEL VALVES needed to upgrade the cutting operation during the production of their 24' diameter split gate 4A topside through-conduit valves, they naturally turned to Prosaw to provide the solution.

Although the existing process utilised a vertical bandsaw, it was very wasteful of material, typically deviating from it’s true path by up to 1/2' on either side of the blade, requiring a considerable amount of post cutting additional machining in order to form a true surface.

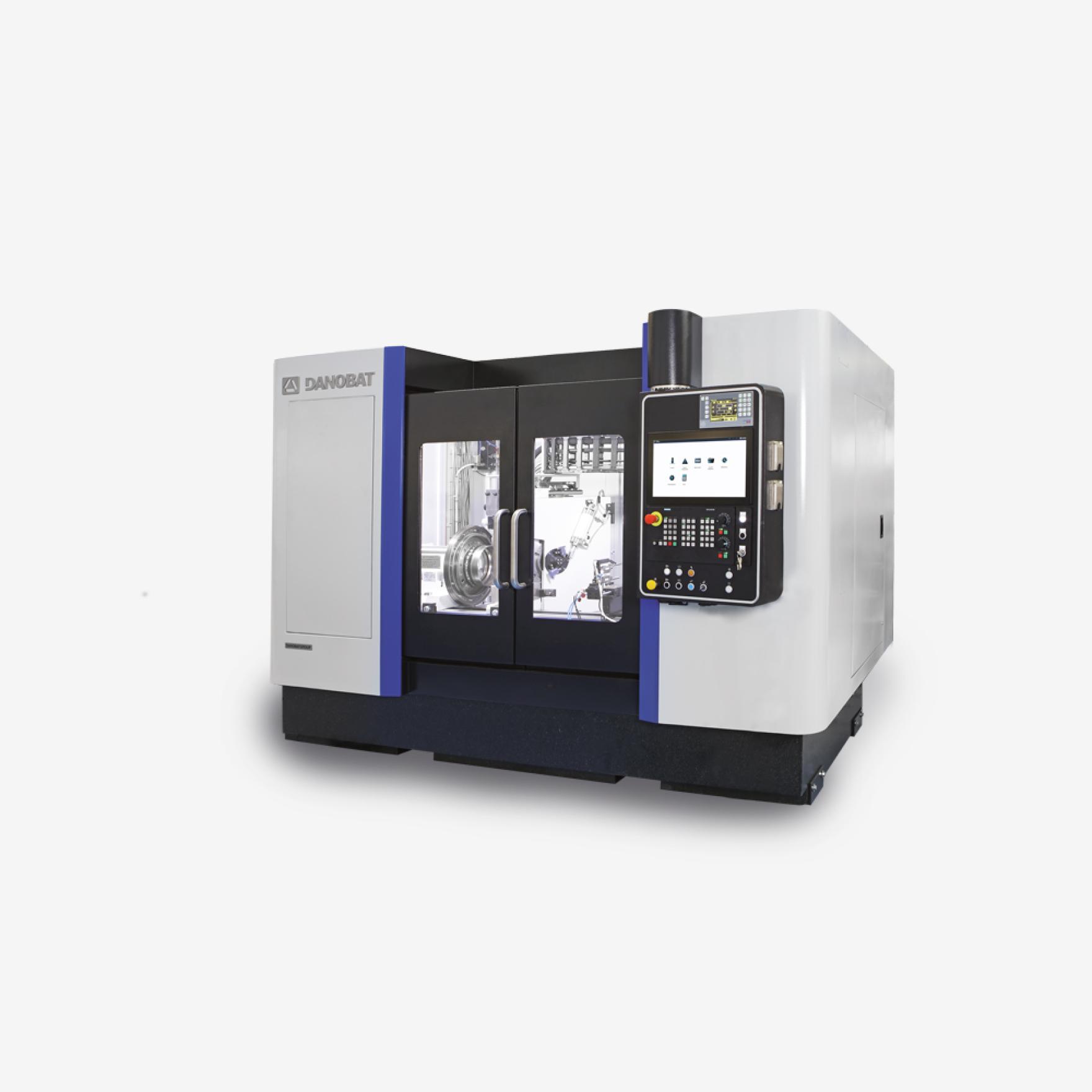

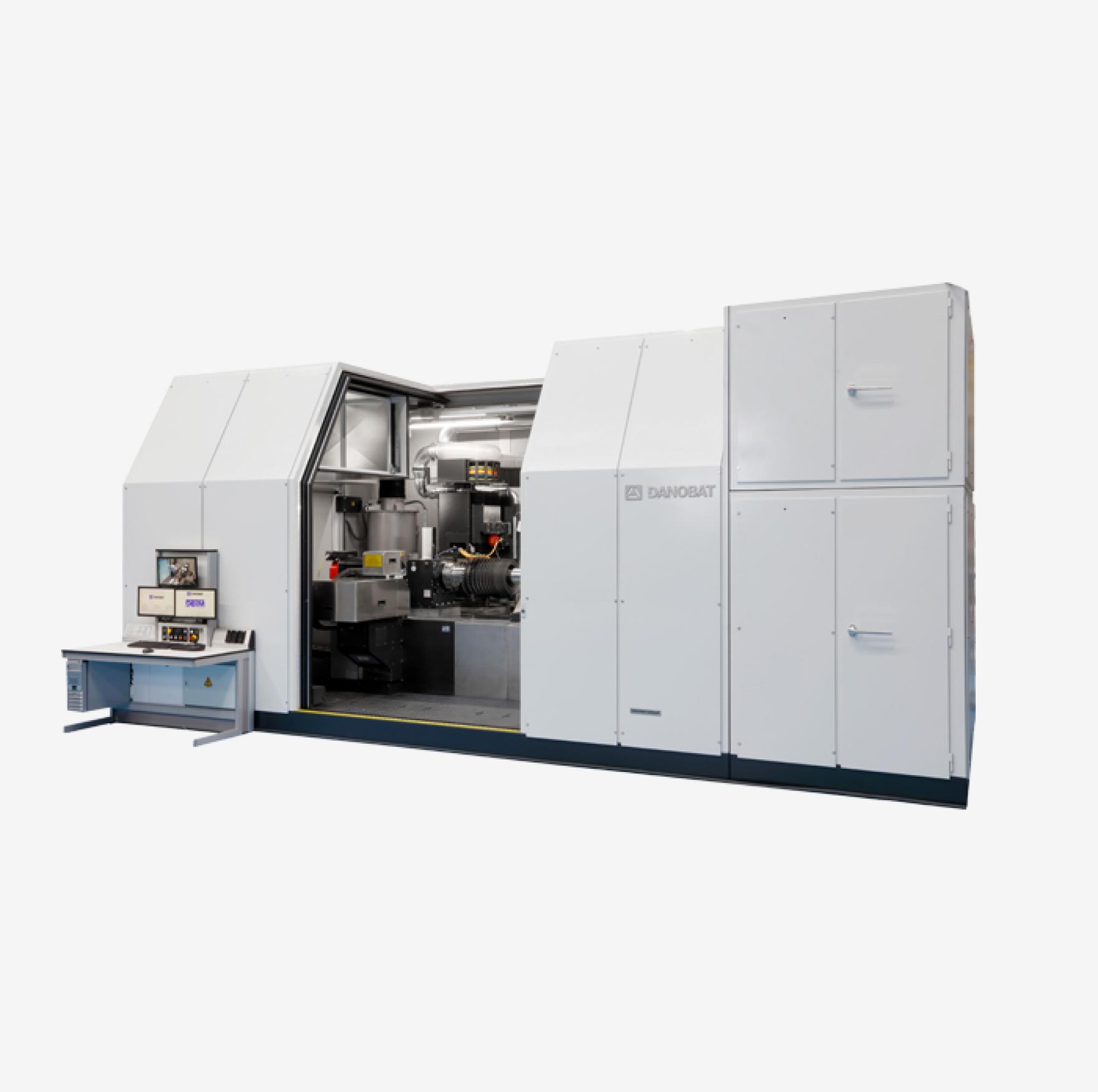

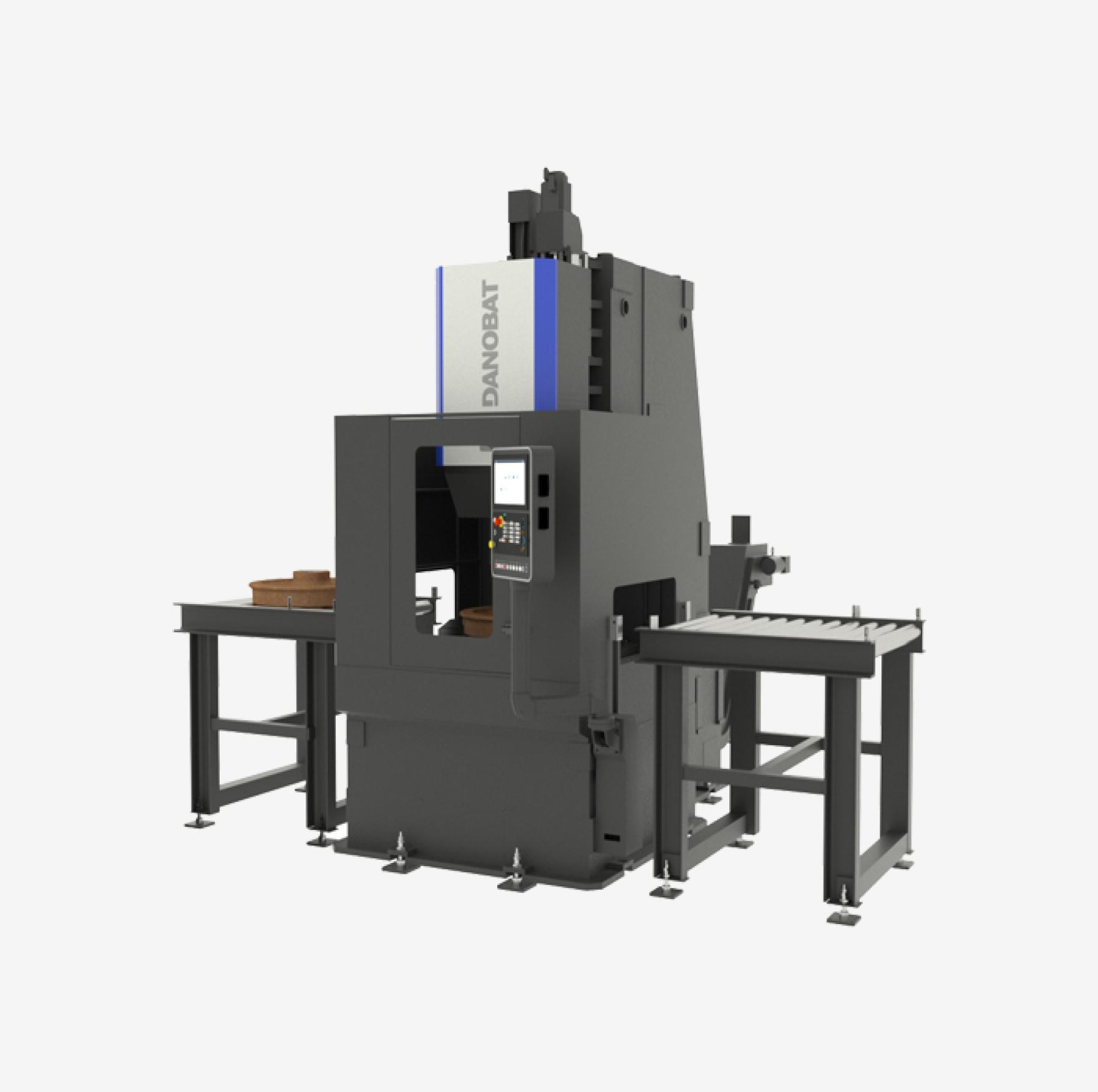

Prosaw’s response was to specify a DANOBAT VL vertical bandsaw, which has drastically reduced the cutting time for this product from 18 hours to just 6 hours, whilst simultaneously reducing waste material due to the appreciably more accurate cutting path, amounting to cost savings in the region of £1,500 for each valve.

Additionally, further significant cost savings have been achieved by the use of a new type of carbide saw blade, that has a life of more than 50 times that of the previous machine.

As Mr. Adam Leggett, Shop Manager, said, “We have been very impressed by this new DANOBAT machine. It is far more accurate and much faster compared to our previous system, and has created huge cost savings. It has also been responsible for relieving bottlenecks in production, causing work to flow more smoothly through the workshop. DANOBAT and Prosaw have been with us every step of the way with this project, giving us excellent service and full sales and technical support which has assisted us greatly in bringing this product along.'