Email us

How to increase the efficiency of railway wheelset maintenance shops

In this video you will get information on the solutions we offer to optimise each of the following maintenance tasks usually carried out in a wheel shop.

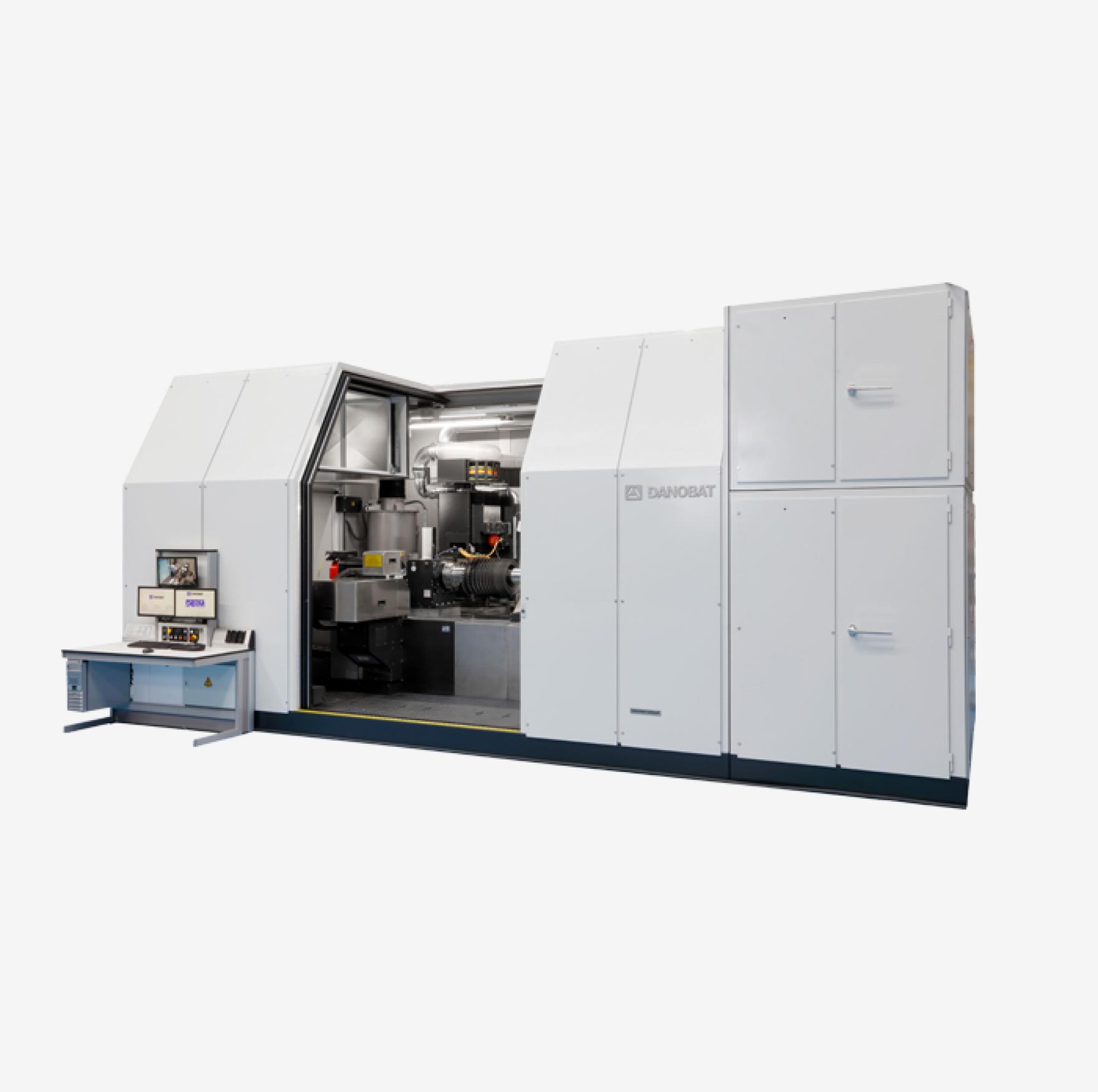

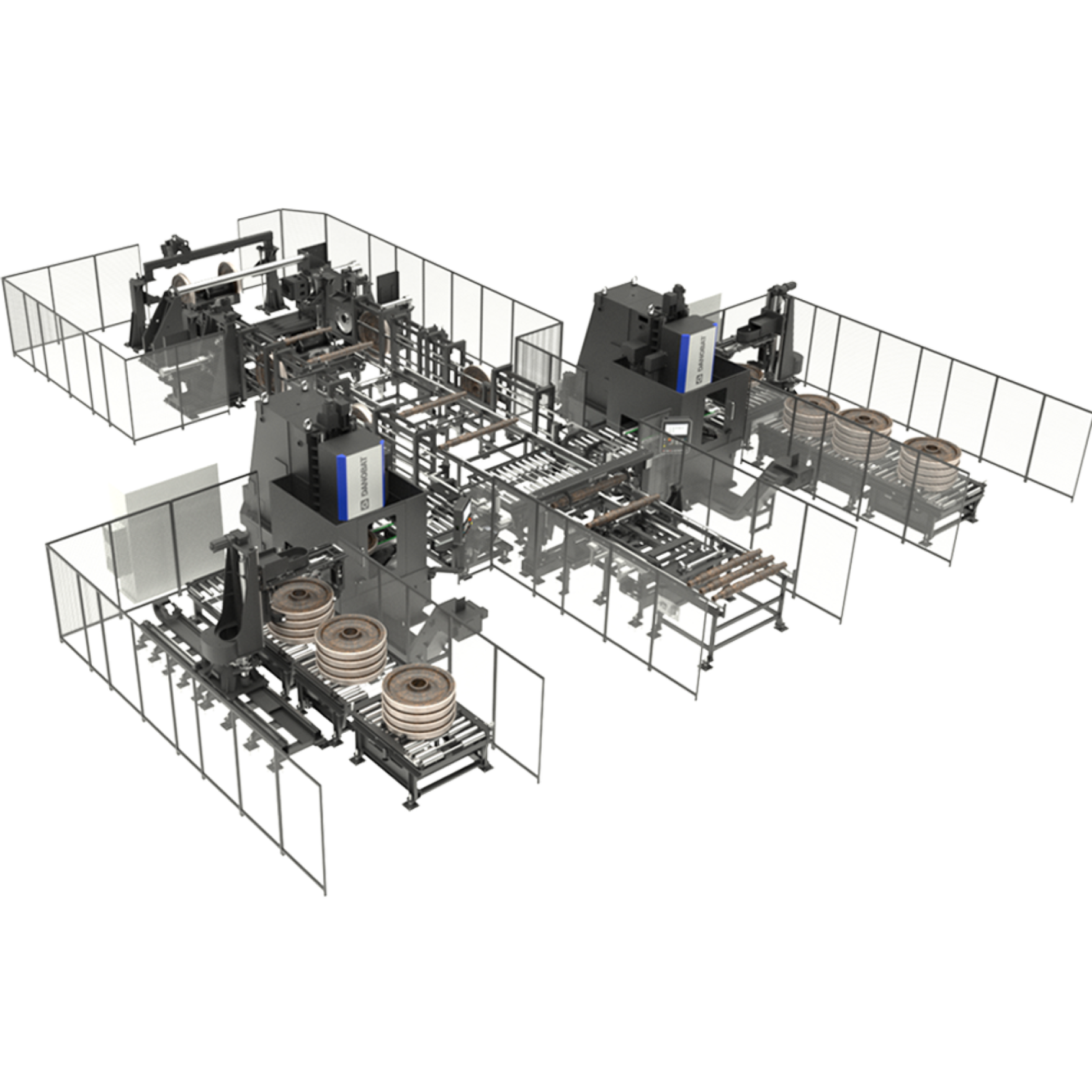

Wheelset maintenance usually starts with a bearing and end cap disassembly area. Next, there is an inspection and diagnosis phase that combines automatic measuring methods and visual inspections.

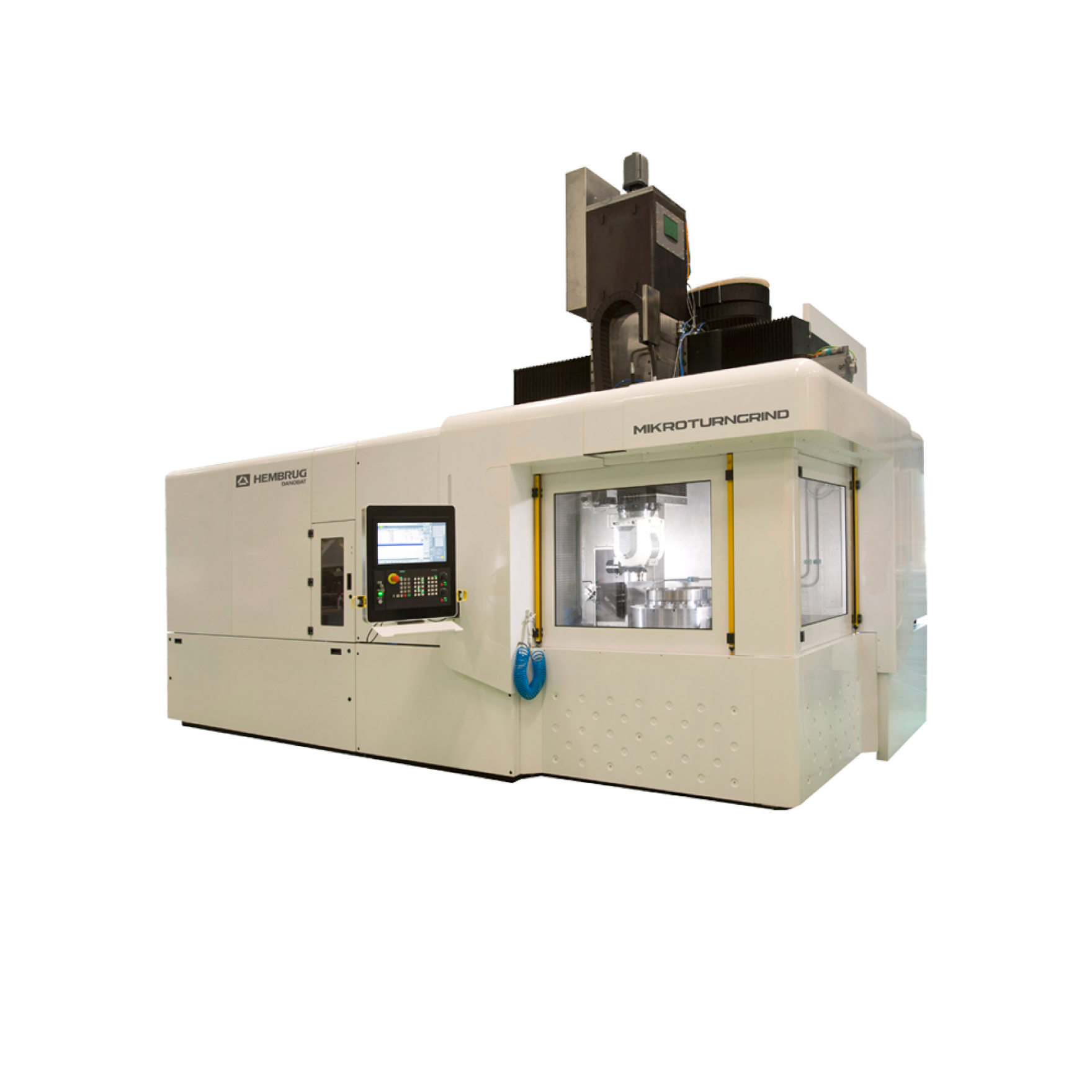

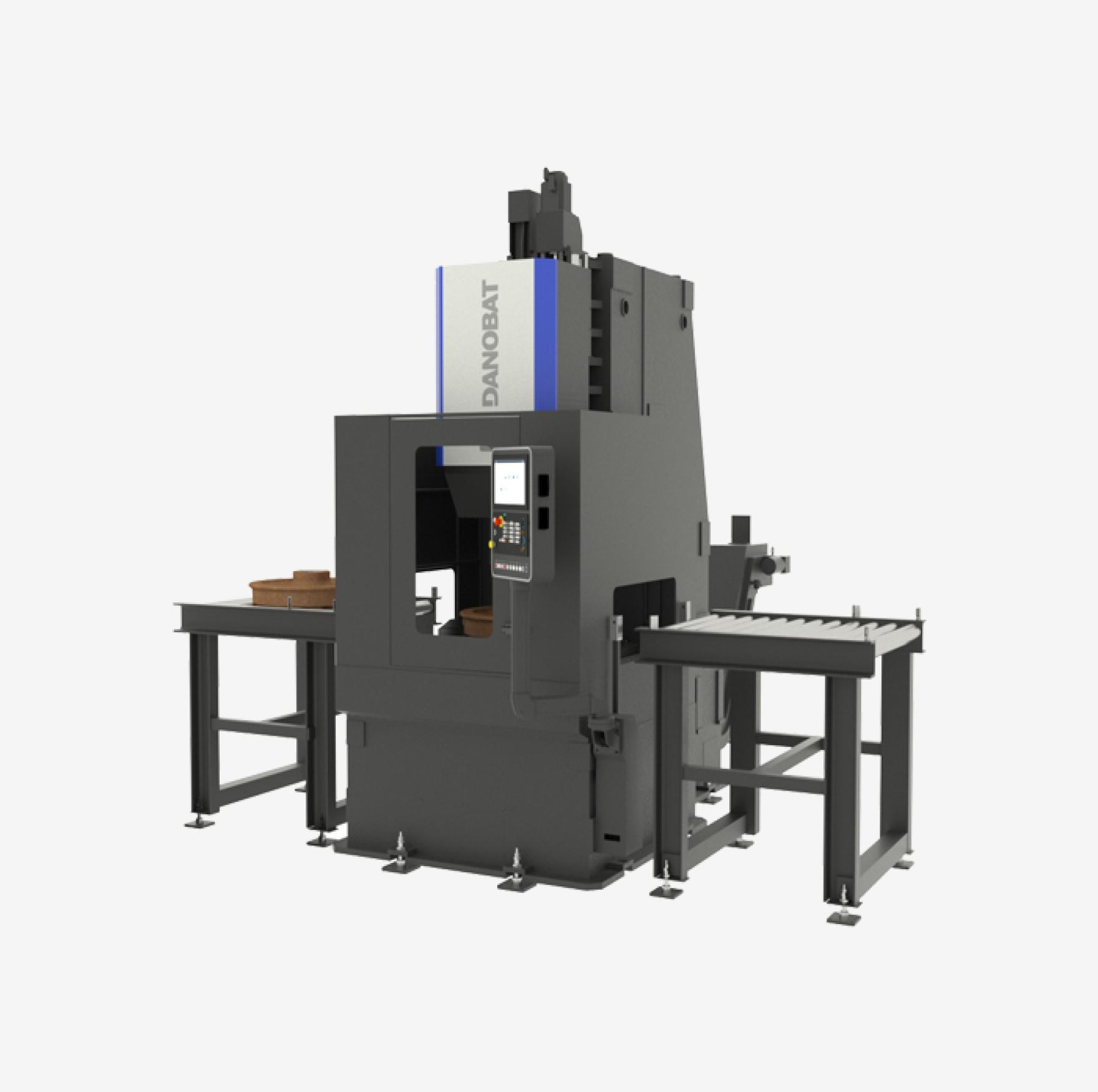

Depending on the incoming status of the axle and wheels, they can be diverted to the WR reprofiling & inspection area, or it can go to the disassembly and refurbishment area.

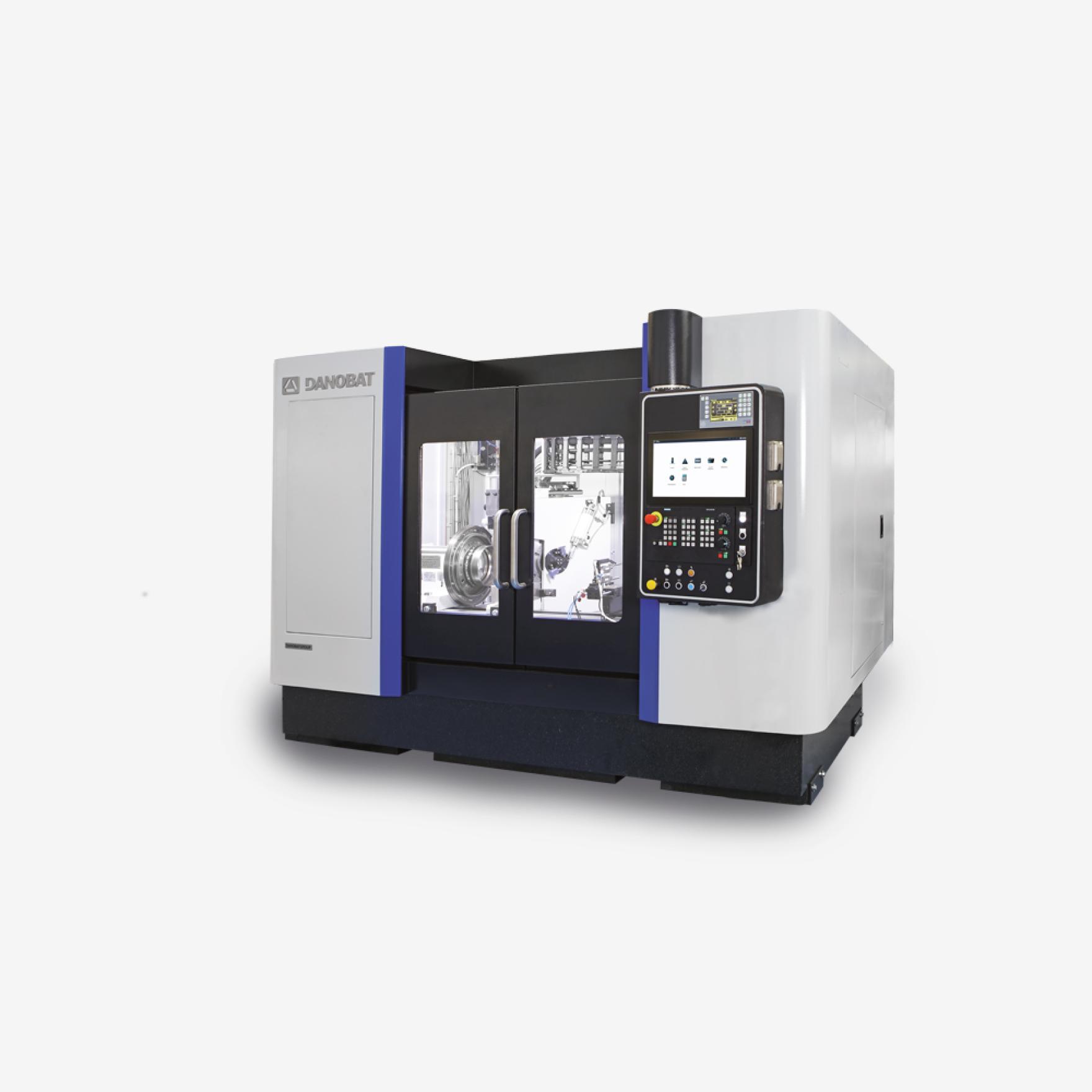

If the wheels are dismounted from the axle, it is necessary to refurbish the axle (UARC), and the boring and press cell (BC) will remount the wheels to the axle.

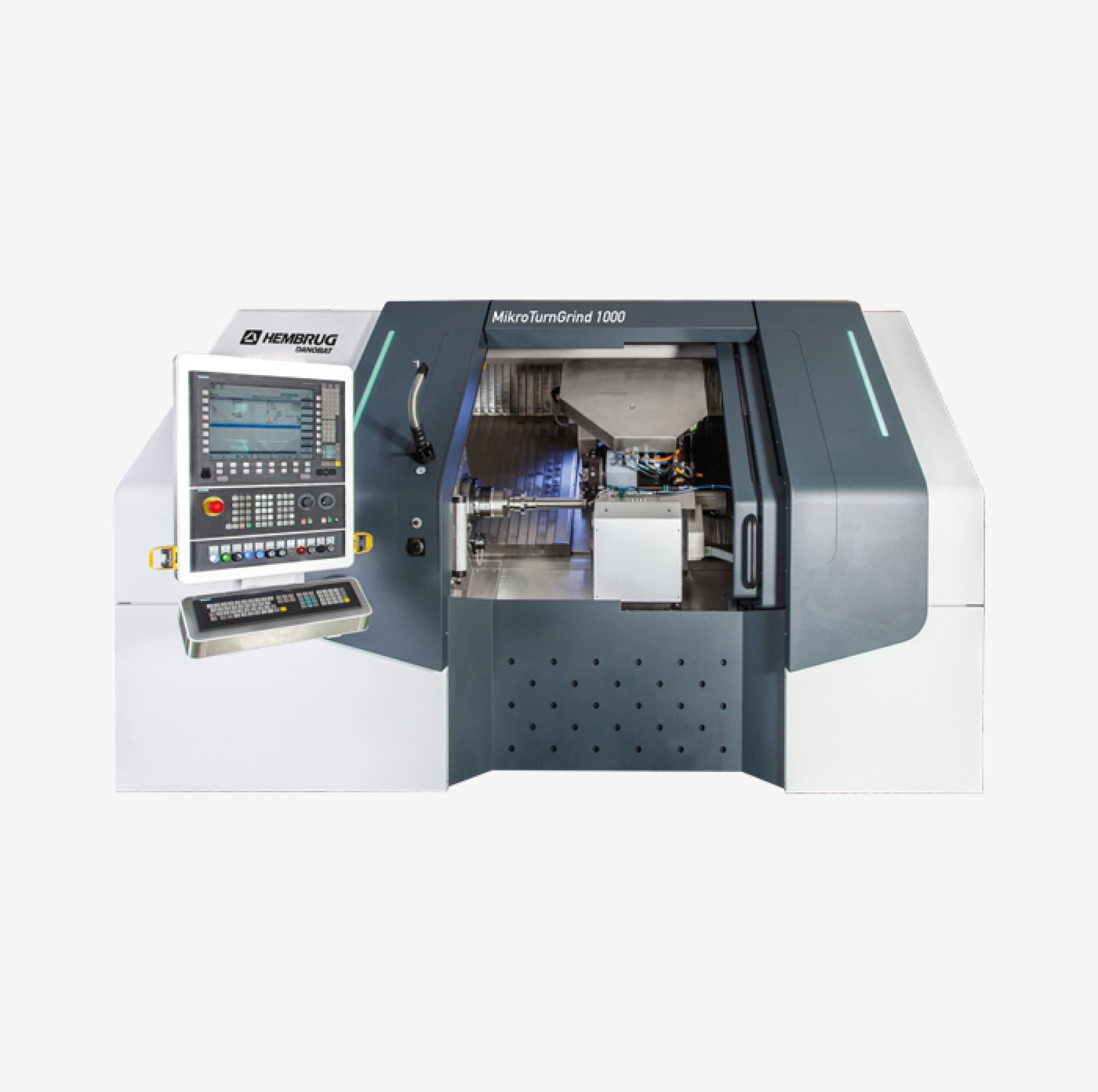

In both cases and after final inspections, bearings and end caps are remounted onto the wheelset to complete the overall wheelset maintenance process.

If you are interested in how to increase the efficiency of railway wheelset maintenance shops, watch the video below.